Factory

Production Center

100,000-Class Clean Workshop

The production workshop is a 100,000-class clean workshop, strictly following the operational standards of international food safety systems such as HACCP and GMP. For each product, we have strict food safety standards. Based on our strict pursuit of standards, we ensure the overall production environment meets the 100,000-class cleanliness standard through high-standard factory hardware, advanced production equipment, and strict environmental control, thus guaranteeing the safe production of food.

Advanced Production Equipment

The Overall Production Standards Reach the Industry-Leading Level

The enterprise has introduced cutting-edge domestic and foreign facilities and equipment, such as automatic glue box machines, automatic cartoning machines, metal detectors, X-ray machines, etc. These have achieved production capacity upgrades, steady growth in output, an improvement in production quality, and a reduction in labor time costs. The overall production standards have reached the industry-leading level.

Improved Quality Control System

Realized Traceable Quality Assurance Management

The enterprise has obtained certifications including BRC, HACCP, ISO9001, ISO22000, KOSHER, HALAL, and NOP (US and EU organic food processing and organic banana planting base certifications). It has been rated as an "AA"-level management enterprise by CIQ (Customs Inspection and Quarantine) and is one of the first batch of enterprises to implement the "Three Simultaneities" standard (same line, same standard, same quality for domestic and export products) and serve as a demonstration enterprise. A professional quality control team follows up the entire production process, strictly inspecting all raw materials, semi-finished products, and finished products. Quality is controlled layer by layer from the source of raw materials, with emphasis on process control. The company has established a complete, controllable, guaranteed, and traceable quality assurance management system.

Strong Innovation Capability

Focused on Freeze-Dried Food R&D and Production for 18 Years

Founded in 2009, the Lixing R&D Center boasts a professional R&D team of 40 members. Collaborating with scientific research institutions such as the Institute of Food Processing of the Chinese Academy of Agricultural Sciences, the School of Food Science at Jiangnan University, Dalian Polytechnic University, Tianjin University of Science and Technology, Fujian Agriculture and Forestry University, and Fujian Academy of Chinese Medical Sciences, the company continuously enhances its R&D strength and innovation capabilities. Up to now, it holds 41 authorized patents, with 100% transformation of patented technologies into practical applications. In the past three years, it has completed 19 key scientific and technological achievement projects at the municipal and county levels, all with a 100% success transformation rate. The company attaches great importance to standardization promotion, taking the lead in drafting and formulating multiple freeze-dried food industry standards, actively participating in the development of national standards for freeze-dried foods, and striving to promote the orderly and healthy development of the freeze-dried food industry.

The First CNAS-Certified Laboratory in the Industry

The Food Safety Testing Center of Fujian Lixing has obtained CNAS certification (China National Accreditation Service for Conformity Assessment). In its 1,000-square-meter laboratory, there are 16 senior inspectors. The testing capabilities cover baby food and dairy products, with main equipment including gas chromatographs, liquid chromatographs, semi-preparative liquid chromatographs, atomic absorption spectrometers, atomic fluorescence spectrometers, and a hundred-grade microbiology laboratory. It can conduct tests on nutrients, melamine, nutritional components, heavy metals, etc., in baby food. Advanced testing equipment and technologies, together with comprehensive testing capabilities, safeguard food safety.

The Most Influential Freeze-Dried Food Enterprise in China

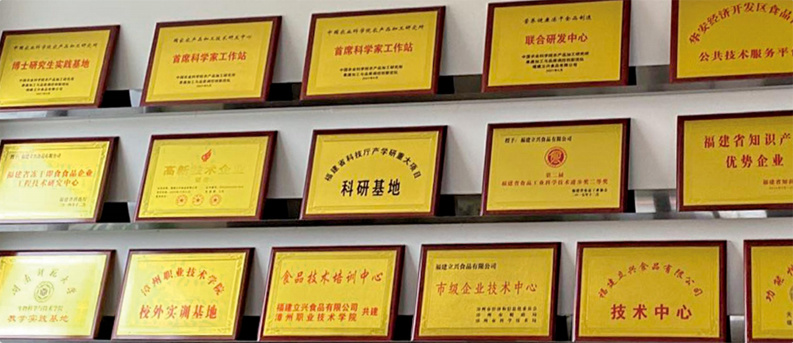

The enterprise has successively been awarded the following honors:

- Chairman Unit of the Freeze-Dried Food Working Committee of the China Food Industry Association

- Vice Chairman Unit of the Special Food Working Committee of the China Food Industry Association

- National High-Tech Enterprise

- National Green Factory

- National Demonstration Enterprise in Agricultural Product Processing

- National Intellectual Property Advantage Enterprise

- Food Supplier for the Xiamen BRICS Leaders' Meeting

- Large Taxpayer

- Provincial Key Leading Enterprise in Agricultural Industrialization of Fujian Province

- Fujian Provincial Advanced Unit in Quality Management

- Fujian Provincial Innovative Enterprise

- Fujian Provincial Post-Doctoral Innovation Practice Base

- Fujian Provincial Benchmark Enterprise in Freeze-Dried Food Production

- Fujian Provincial "Specialized, Refined, Unique, and New" Small and Medium-sized Enterprise

- Fujian Provincial Enterprise Technology Center

- Fujian Provincial Science and Technology Little Giant Enterprise

- Fujian's First Top 100 Brand Value Enterprises

- 2024 "Great Nation Brand" Annual Brand in the National Brand Ceremony of Great Nation Brand

Consult immediately and look forward to communicating with you.

Fujian Lixing Food Co., Ltd. offers professional OEM/ODM services, specializing in freeze-dried fruits, yogurt blocks, coffee powder, etc., partnering with brands like Saturnbird and Bestore, with full-industry chain capabilities and CNAS-certified testing centers.

CONTACT US

CONTACT US

GETA QUOTE

GETA QUOTE